Categories

- Case & News (50)

- Blog (572)

As a concrete mixer manufacturer with over two decades of experience in the concrete mixing equipment field, we have witnessed the industry’s evolution from steam power to intelligent control. We deeply understand that the core of a high-quality concrete mixer is never simply “mixing,” but rather achieving macroscopic uniformity and microscopic fusion of cement, sand, water, and admixtures through scientific structural design and power transmission, laying a solid foundation for every infrastructure project. Today, we’ll move beyond rigid technical parameters and, based on practical experience, discuss the working principle of concrete mixers and share our reflections on this industry.

The core of a concrete mixer’s working principle lies in the precise coordination of “power transmission + material movement.” The core structure revolves around four major systems: feeding, mixing, water supply, and unloading. While the working logic differs between models, the essence is the same: breaking down material stratification through controllable movement to achieve homogeneous mixing—this is our core understanding, validated through tens of thousands of practical tests, and the starting point for designing every piece of concrete mixer equipment.

Currently, the mainstream concrete mixers in the industry are divided into gravity-fed and forced-flow types. The difference in their working principles stems from the different driving forces behind material movement.

The self-fall concrete mixer relies on the rotation of the mixing drum. Blades on the inner wall of the drum lift the material to a certain height, and then the material falls freely under its own weight. Through repeated “lifting-falling,” the material particles interweave, collide, and tumble, ultimately achieving uniform mixing. This type of machine has a simple structure and low energy consumption, making it suitable for mixing plastic concrete. In our production, we have found that even slight adjustments to the blade angle (with an error of no more than 3°) can significantly improve the uniformity of mixing, which is why we adhere to the details of precision manufacturing.

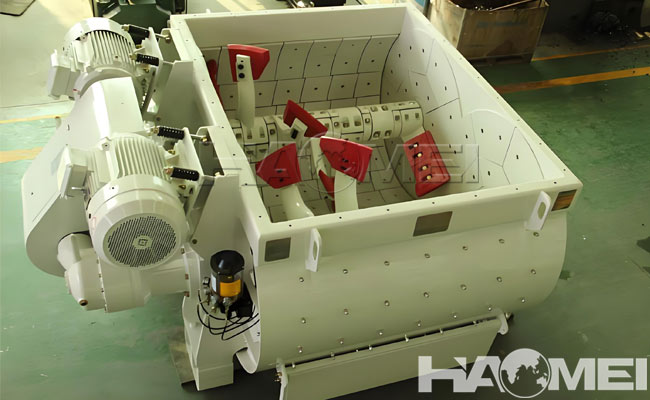

The forced type concrete mixer is currently the mainstream choice for high-end projects. Its core logic is “active mixing and forced fusion.” The mixing drum remains stationary, while the internal mixing shaft drives multiple sets of staggered blades to rotate at high speed. The blades apply radial, circumferential, and vertical shear forces to the material at different angles, while simultaneously squeezing and throwing the material to fill the gaps created by the blade rotation. Based on our R&D experience, the twin-shaft forced concrete mixer has the best mixing effect. The convection motion created by the counter-rotating dual shafts can break up material clumps in a short time, allowing admixtures to penetrate evenly. This is also the core direction of our optimization for high-strength concrete projects.

Many customers ask, “Why does your concrete mixer equipment produce concrete with more stable strength, even though it’s the same type of mixing?” The answer lies in the meticulous control of the working principle. From the quantitative control of the turbine flow meter in the water supply system (error controlled within ±1%), to the precise timing of the feeding device, and the smooth discharge of the unloading mechanism, the coordination of each link is a precise implementation of the working principle. We firmly believe that the working principle of a concrete mixer is not only about technical logic, but also a manifestation of “meticulous adaptation to needs”—for example, for high-temperature environments overseas, we optimize the arrangement of the mixing blades to reduce heat generation from material friction; for the flexible needs of small and medium-sized infrastructure projects, we simplify the operation process, making the principle more practical.

Having cultivated the industry for many years, we have witnessed the transformation of concrete mixers from “extensive mixing” to “precise and controllable” mixing, and we deeply understand that the essence of the working principle is “adaptable to engineering.” As a concrete mixer manufacturer, we must not only master core technologies, but also integrate industry experience into every design aspect, transforming complex working principles into stable, efficient, and energy-saving equipment performance. In the future, we will continue to delve into the field of mixing, optimize the implementation of principles based on practical experience, and use our meticulously crafted equipment to build a solid foundation for every infrastructure project worldwide.