Categories

- Case & News (50)

- Blog (571)

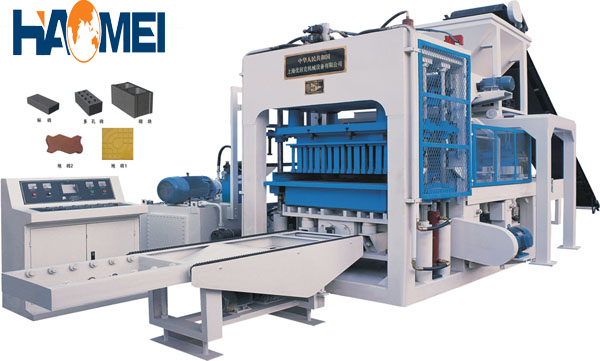

The performance characteristics of QT6-15B brick making machine

1, The mold box adopts air spring clamping to achieve the best damping effect, which can effectively reduce the noise generated by vibration equipment, and can achieve effective control of load measurement and the product to ensure consistency of products.

2, Use PLC intelligent control and man-machine dialogue system, easy to achieve random signal analysis, fault diagnosis and a variety of parameter settings to ensure that the best work results. The user-friendly design patterns, technical parameters is adjustable at any time, through technical research use of scientific and technological means of mechanical and electrical integration of the design concept, use of super steel, its products are extremely strong and durable.

3, Use advanced Promise frequency technology in brick making machine, exciting force can be adjusted according to the requirements of different products to ensure product quality. Integrated vibration table and full synchronous vibration mode, so that the machine to achieve the best realistic effect.

4, Use special double-ended output swing technology, optimize the layout of the vibrator, makes vibration evenly distributed in the swing table, thus ensuring the uniformity and consistency of products.

5, Use four-way guide and lengthened wear-resistant guide sleeve to ensure accurate movement of mold and indenter. The charging box adopts guided operation to reduce the mold load, to achieve the best fabric.

6, The hydraulic system using Germany imported hydraulic original. Use simple automatic stacking device, significantly reducing the labor intensity.

7, The energy-saving, in operation. The use of large displacement hydraulic pump, the system runs fast. To avoid the waste of labor needed to dry production and occupation of the site of the drawbacks, saving the cost of buying pallets.

8, With high yield, good product density, the product can be achieved to be palletizing. The convex and concave adopt with rack balance system, mold is more stable in operation.