QT Brick making machine

CATEGORY AND TAGS:Brick Making Machine brick making machine, brick making machine for sale, brick making machine price, brick making machine price list, bricks making machine, bricks manufacturing machine, soil brick making machine

- Condition: New

- Delivery port: Qingdao or Tianjin port, China

- Payment term: L/C, T/T

- Guarantee period: 12 months

- Delivery time: 10-15 days after received deposit

- Installation time: 20days

- Specifications

- Capacity

- Our Strength

- Our service

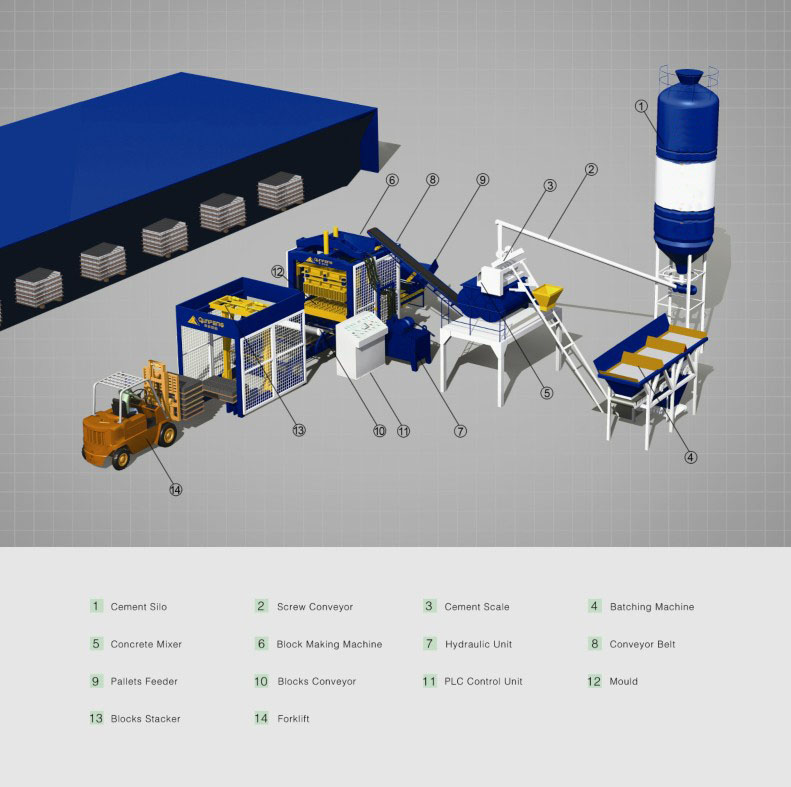

Haomei is one of the prominent manufacturers and suppliers of brick making machine, Cement Blocks Machine, concrete block making machine. Offered at affordable costs, these high functionality machines come with three sections such as mold box, stripper head and vibrator unit. Because of the 1000-1200 blocks in 8 hrs and 4000 bricks in 8 hrs of output, this range is highly appreciated among in the industry.

Technical parameters

| Model | dimensions | weight | molding cycle | pallet size | power | the highest frequency |

| QT3-15 | 4100×1600×3000mm | 4.5t | 15-20S | 730×580×30mm | 20kw | 4800-5100(r/min) |

| QT4-15 | 5420×1550×2940mm | 6.5t | 15-20S | 850×570×30mm | 20kw | 4800-5100(r/min) |

| QT6-15 | 6350×1680×2850mm | 8t | 15-20S | 850×700×25mm | 29kw | 4800-5100(r/min) |

| QT8-15 | 4750×2000×2950mm | 10t | 15-20S | 1080×700×25mm | 33.55kw | 4800-5100(r/min) |

| QT10-15 | 8200×2000×2950mm | 11t | 15-20S | 1150×840×40 | 36.55kw | 4800-5100(r/min) |

| QT12-15 | 8200×2300×3000 | 13t | 15-20S | 1310×840×40mm | 46kw | 4800-5100(r/min) |

| QT15-15 | 5700×2500×3400 | 16t | 15-20S | 1320×1100mm | 48kw | 4800-5100(r/min) |

Technical features

- Excellent production rate

- Corrosion resistant finish

- Sturdy construction

- Easy operations

- Longer functional life

- Reliable performance

Classic mode of vibration, it is particular suitable for producing high-strength blocks, standard bricks with short molding cycle and high efficiency. It takes the most advance mould vibration technology, with the frequency control of motor speed, powerful force and the forming density products.

Special system for sending the boards can prolong the useful time the boards. Automatic PLC control systems, interactive user interface,the control system, security configuration logic control,production procedures and fault diagnosis display function.

| modle | product name | product specifications | number per plate | block/h | block/8h |

| QT3-15 | block | 390×190×190 | 3 | 540 | 4320 |

| brick | 240×115×90 | 11 | 1980 | 15840 | |

| standard bricks | 240×115×53 | 22 | 3960 | 31680 | |

| QT4-15 | block | 390×190×190 | 4 | 720 | 5760 |

| brick | 240×115×90 | 12--14 | 2160--2520 | 17280--20160 | |

| standard bricks | 240×115×53 | 24--26 | 4320--4680 | 34560--37440 | |

| QT6-15 | block | 390×190×190 | 6 | 1400-1080 | 11520-8640 |

| brick | 240×115×90 | 15 | 3600-2700 | 28800-21600 | |

| standard bricks | 240×115×53 | 36 | 7920-5940 | 63360-47520 | |

| QT8-15 | block | 390×190×190 | 8 | 1920-1440 | 15360-11520 |

| brick | 240×115×90 | 22 | 5040-3780 | 40320-30240 | |

| standard bricks | 240×115×53 | 45 | 10080-7560 | 80640-60480 | |

| QT10-15 | block | 390×190×190 | 10 | 2400-1800 | 19200-14400 |

| brick | 240×115×90 | 27 | 5760-4320 | 46086-34560 | |

| standard bricks | 240×115×53 | 54 | 12240-9180 | 97920-73400 | |

| QT12-15 | block | 390×190×190 | 12 | 2160 | 17280 |

| brick | 240×115×90 | 30 | 7200 | 57600 | |

| standard bricks | 240×115×53 | 60 | 14400 | 115200 | |

| QT15-15 | block | 390×190×190 | 15 | 2700 | 21600 |

| brick | 240×115×90 | 40 | 9600 | 76800 | |

| standard bricks | 240×115×53 | 80 | 19200 | 153600 |

The best professional manufacturer of brick making machine in China

- The factory covering 200,000㎡, 500 workers, 35 engineers, and 90 technicians.

- HAOMEIprovide the turn-key project for our customer, including concrete block making plant, concrete batching plant and AAC plant

- With independent right to export, HAOMEI is the first company in China to export the block making plant to overseas market. Until 31st, May 2013, HAOMEI has exported to 106 countries and region all over the world.

- Certificate:EU CE, ISO9001, ISO Quality Management System, ISO14001 Environmental Management System.

- 50 technicians work overseas to do the service for our customers in different countries.

Pre :to guide customers to choose the most suitable equipment. Free of charge to professional engineering and technical personnel to the site for users planning , design the best site production process. According to the different requirements of customers , design and produce your required products .

Sale : The production process in strict inspection of parts. In according with the contract on time delivery

Customer service : Assigned to the professional and technical personnel , to the scene to guide customers to install. Be responsible for equipment debugging. Responsible for on-site training operations and technical personnel. Complete sets of equipment after installation , the company designated professional and technical personnel all year round to provide technical services, until the user satisfaction.